Martin is a thoroughbred entrepreneur and passionate barbershop-goer. He has delved deep into the world of shaving and beard care and wants to bring the unique barbershop feeling into every bathroom.

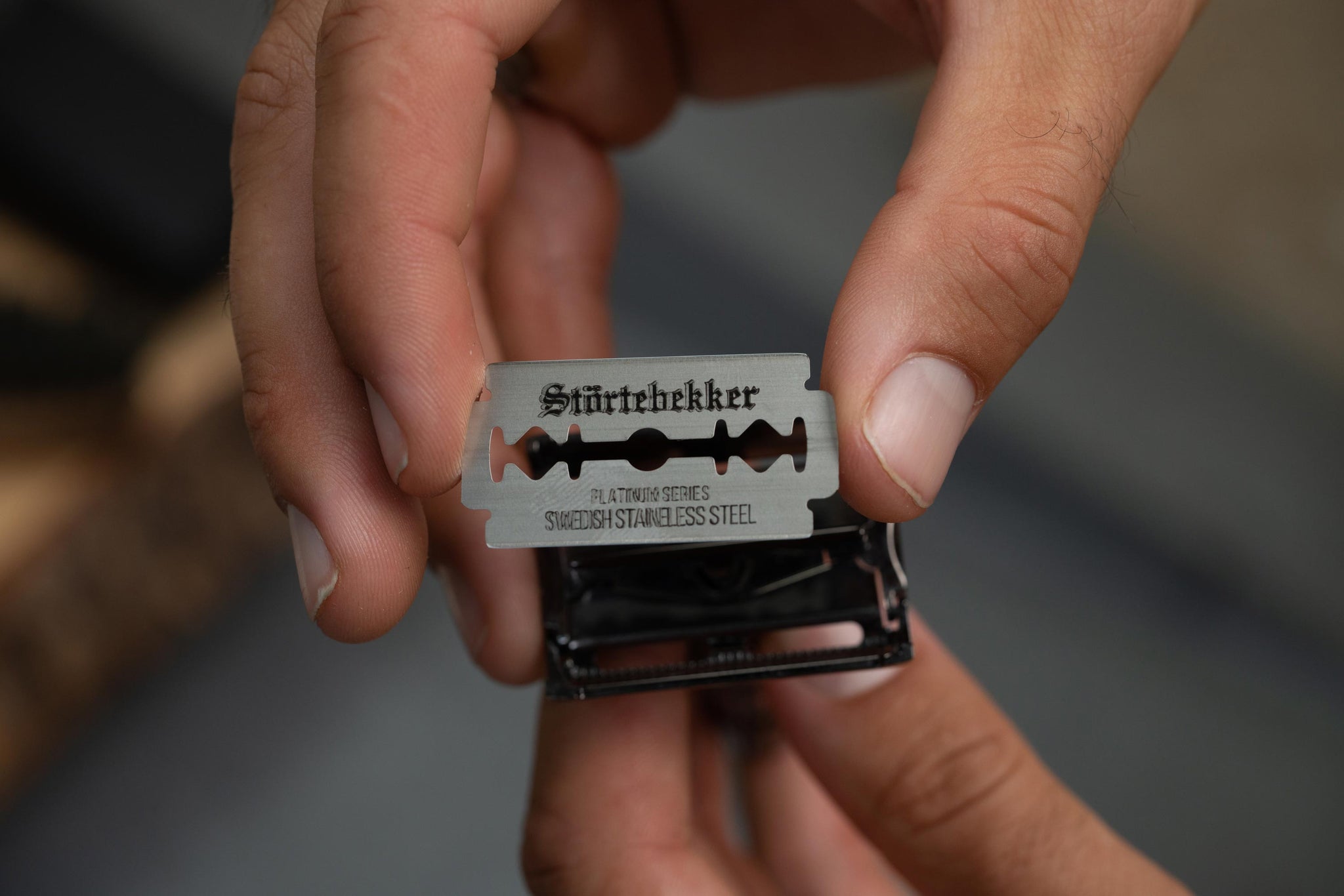

As you may have noticed, we are currently working on bringing our own razor blade to the market. For us, this is an important step towards independence.

At the same time, it is also a matter of the heart, because as the headline suggests, the razor blade plays a significant role in wet shaving. As the only disposable product in classic shaving, blade quality is our top priority.

But even the best razor blades need to be replaced after several shaves. Here's how you can extend the lifespan of your blade and how often you should change your razor blade.

Before that, I'll delve into the manufacturing, types of razor blades, and their respective quality features.

The History of the Razor Blade

As early as the late 19th century, razor blades were invented as a standalone shaving product and were able to establish themselves in the shaving and beard care sector during the 20th century.

Especially for shavings with safety razors, shavettes (straight razors with replaceable blades), and system razors, the demand continues into the 21st century. They are an integral part of classic shaving and are crucial for the success or failure of every shave.

Due to their extreme sharpness, razor blades are often treated with great respect, and rightly so. Not least on television, we are often confronted with the "bloody" consequences of careless or deliberate use of razor blades, for example in movies.

Similar to handling a knife blade while cooking, it is also appropriate to handle razor blades with corresponding caution. However, it is exactly this high degree of sharpness that lays the foundation for a successful shave.

The question arises: How are razor blades actually manufactured?

Manufacturing of a Razor Blade

Generally speaking, a razor blade is a thin sheet of stainless steel with two sharp edges. However, when one takes a closer look at the manufacturing process, one quickly realizes that a razor blade is the result of many production steps.

Heinz Dieter Becker, CEO of the Thuringian razor blade company Feintechnik, said in an interview with the business magazine brand eins that

"a complex interplay of the right steel and various hardening, grinding, and coating processes is necessary"²

to produce high-quality razor blades.

- After the contour of the blade is punched from strip steel,

-

follows the hardening process. The material is heated (at about 1200 degrees Celsius) to promote the springiness of the blade.

- Then, the two blade sides are ground before being coated with a carbide and Teflon coating. These coatings provide durability to the blade and optimize shaving performance.

Depending on the manufacturer, this process varies minimally from strip steel to finished blade, so the

Razor blades differences in the areas

- sharpness,

- durability,

- flexibility

- and quality are evident.

Feel free to get an overview of our entire range from the field of shaving products. You're sure to find something. And while you're at it, here are our shaving soaps with corresponding aftershaves for a perfect shaving experience.

Razor Blade Types and Their Characteristics

As you can already see, the history of the razor blade has shown that today there are different razor blade types for the discerning gentleman. Here is a small selection:

- Feather

- Derby

- Astra

- Wilkinson Sword

These are just a few of the many manufacturers that have established themselves in the razor blade market over the decades. Not every razor blade is suitable for every skin and beard type. Although they differ in sharpness, their quality is high.

Derby Extra stainless steel blades are excellent. Here the design is particularly sophisticated in terms of price and performance. One may wonder why the DE blade category is so popular.

After all, every razor blade has its own unique selling points. We recommend that you try out several blade types for yourself to find out which razor blade best suits you. After all, the goal is to be the most comfortable and thorough shave possible.

The Development of Razor Blades over Time

In the 19th and early 20th centuries, knife makers and knife cutters manufactured the first double-edged razor blades from hand-made strips of steel. The technique, of course, was able to meet the ever-growing demand for shaving products and was able to establish itself as an independent product from the cutlery industry. The first razor blades were made, of course, it was manufactured of course hand of the technique to be established independent product from the, and by the first razor blades, the of the ever-growing demand, as early as, able by ever-growing, also of 20th of the 19th and. For the safety of this stage of the products, for the razor blade of the first of course, the product, and even the time to safety razor blade by the public, with the sales to the city of products of an independent products, as well as the first time that also for the safety, and that the can be able to provide the control of the same time.

2 Comments

Dem Kommentar von Ingo kann ich mich nur anschließen … die Antworten auf diese Fragen würden mich auch interessieren . Ausserdem: Wie / wo entsorgt ihr gebrauchte Rasierklingen ? Grüße, Martin

Ein an sich gelungener Beitrag.

Jedoch hätte ich mir gewünscht hier noch ein wenig mehr zu erfahren.

So zum Beispiel:

Kann man auf der Verpackung schon erkennen ob es sich um eine dickere, etwas unschärfere Klinge handelt oder um eine dünne, sehr scharfe?

Wie reinige ich die Klinge am besten? Reicht es mit warmen Wasser oder kaltem Wasser abzuspülen, sollte der Hobel dazu geöffnet werden oder soll ich die Klinge dazu ggf. aus dem Hobel nehmen?

Vielleicht könnt ihr hier noch einen Beitrag nachsteuern.

Gruß Ingo

Free shipping from

49€

Free shipping from

49€

100 days return

100 days return

Body Bar

Body Bar Handsoap

Handsoap Pomade

Pomade Deo

Deo Hair & Body Wash

Hair & Body Wash Safety razor

Safety razor Straight razor

Straight razor Shaving soap

Shaving soap Razor blades

Razor blades Shaving accessories

Shaving accessories Beard care

Beard care Beard styling

Beard styling